Make Automatic Palletizing Work For You

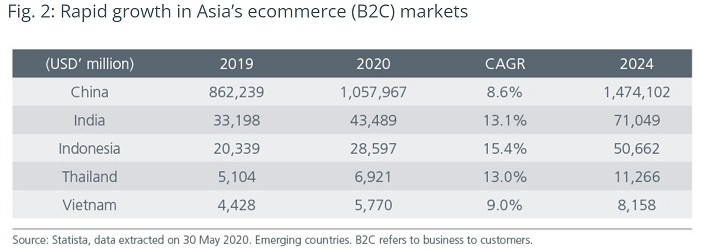

The world has seen exceptional growth in e-commerce transactions in recent years. Asia, with its growing middle class and increasing internet penetration, is at the forefront of global e-commerce dynamism. The region accounted for 57.4% of global e-commerce sales (business-to-consumer) in 2019. According to Statista, Asia’s e-commerce revenues are predicted to grow by 22.4% to USD1.36 trillion in 2020 and reach USD 1.92 trillion by 2024. By then, Asian economies will account for 61.4% of the global e-commerce market. While China is a market leader in terms of size, the e-commerce markets in India and Indonesia the world’s second and fourth most populous countries, respectively – are expected to enjoy double-digit growth rates in the coming years (Source: EastSpring Investments - E-commerce: Driving Asia’s next leg of growth, July 2020).

The growth of e-commerce, which accelerated further with the Covid-19 pandemic, has drastically changed the logistics landscape. With consumers today increasingly shopping online and expecting fast delivery, warehouse, distribution and fulfilment centre operators are feeling the need for more streamlined logistics and greater efficiency more than any other industry. Surging demand and labour shortage have turned many businesses to smart automation solutions, like collaborative applications.

A collaborative application is more than just a cobot. John Santagate, Research Director for Commercial Service Robotics at IDC, says, “Innovation has occurred with regard to robotic arms over the past several years, delivering robots that are precise, powerful, and collaborative. However, the robot doesn’t complete any tasks without end-of-arm tooling. The innovation that is occurring in the field of end effectors is the next frontier for collaborative robotic innovation. As collaborative robotic arms move towards commoditization, the innovation occurring around the end-of-arm tooling will enable organizations to deploy robotic technology in new ways.”

Collaborative applications can accurately handle repetitive, injury-prone, time-consuming tasks that aren’t ideal for human workers. In logistics and warehouse, collaborative applications can be easily implemented with one cobot and collaborative EoAT (end-of-arm tooling) for packaging and palletizing processes. With versatile, collaborative EoAT, the robotic application can be easily redeployed if products or logistics contracts change.

With a line of plug-and-produce collaborative grippers, a single robot can also be used for multiple processes. For instance, a finger gripper can be used to pack a box with parts, then can be changed for a vacuum gripper to palletize. Dual grippers can precisely palletize two different shapes and sizes of boxes at the same time, and new electric vacuum grippers eliminate the need for an external air supply and hoses. Stacking and packaging tasks that require a human sense of touch can be automated quickly and easily with the addition of force/torque sensing on a finger gripper, which supports even delicate packaging applications such as placing parts in a blister pack. (Read more: http://en.onrobot.info/ap-ebook-palletizing)

4 KEY COLLABORATIVE APPLICATION BENEFITS:

1. SAFE COLLABORATION WITH HUMAN WORKERS

Collaborative applications don’t require safety fencing (subject to a risk assessment). They can complete tasks alongside your worker's safely and the robots themselves are flexible and they can be easily moved around the factory floor.

2. EASE OF USE AND PROGRAMMING

Cobots are known for their easy programming that allows even inexperienced users to “teach” a robotic process by simply moving the robot arm to the desired waypoints and using a touchscreen teach pendant to set the required actions. Collaborative EoAT extends this benefit with easy-to-use programming capabilities for the tool that are accessed directly from the robot’s teach pendant. This is one way that collaborative EoAT helps maximize production with faster uptime. Other ease-of-use attributes to look for include plug-and-produce EoAT implementation with limited cables and connections to manage.

3. FLEXIBILITY FOR EASY REDEPLOYMENT

The ability to quickly and easily redeploy cobots provides numerous advantages for companies with changeable product lines, seasonal demands, or multiple processes that need to be automated using a single robot that is moved between tasks. Cobots can save multiple programs on the teach pendant and with collaborate EoAT, changing jobs can occur in minutes by simply plugging in the new tool and pulling up the right program on the teach pendant. The addition of a collaborative quick changer allows for fast and easy tool changes for maximum uptime and productivity.

4. COST-EFFECTIVE FOR FAST ROI

Low upfront costs and fast ROI are attractive benefits of collaborative applications, especially for small and mid-sized manufacturers. Because the tool is such a critical aspect of the success of the application, collaborative tools must be simple enough to offer quick success even for operators with no previous robotics experience. These tools minimize the number of cables that could interfere with the robot’s actionsor cause downtime, and must be robust enough for ongoing productivity in an industrial environment running 24/7.

Collaborative applications help businesses maintain high-quality standards—and avoid costly product recalls—while simultaneously helping to improve productivity. In addition, worker's safety increases, as robots can step in to fill those roles that are no longer safe or feasible for humans—plus robots can operate continuously. The workers are relieved from manual tasks to do higher value activities. This is especially important nowadays. Overall, businesses can gain competitive advantage through the resulted flexibility