5G and Manufacturing – ctrlX: The Future of Industrial Automation

These days, everyone is accustomed to seeing technology constantly evolving. We see this with operating software, with apps, with mobile devices, and more. The advent of 5G technology represents a huge shift in wireless communications, because for the first time data rates and levels of reliability are comparable to those in the wired environment – in fact, according to a whitepaper developed by Bosch Rexroth, data rates are ten times higher than the generation that precedes them. When everything can work wirelessly in real time, manufacturing can be much more flexible, faster, and cost-effective. Industrial IoT has become a key focus area for the entire 5G ecosystem with specified features created to address needs of industrial use cases and applications. This includes support for real-time traffic, ultra-high reliability and low-latency, time-sensitive networking (TSN) and high accuracy positioning. Factories can be equipped with their own dedicated 5G networks, which are decoupled from the established public networks, to some extent. This gives factory owners more flexibility and independence ways they can make use of 5G. Increasing digitalization and connectivity are changing the requirements as regards to a modern automation system. Independence, connectivity, and real-time capabilities are essential requirements which will shape future solutions. The solution to the challenges described above can be met with a fully open software architecture with flexible app technology. Such a solution stands out with its openness, scalability, modularity, and flexibility. This allows new business models and completely new degrees of freedom for users while offering great potential for savings.

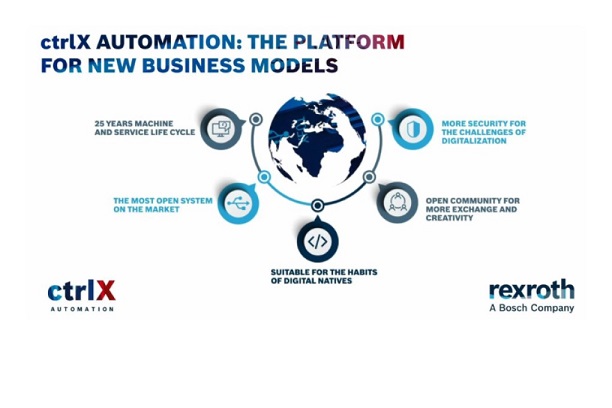

With ctrlX Automation, it will serve as a future proof platform for new business models. ctrlX is an automation platform that focuses systematically on the user. It is flexible and scalable thoroughly with maximum openness at all levels and interfaces. The system functions complement each other perfectly and can also be extended by apps, third-party hardware, and software. Users can put individual solutions into operation much more quickly than before to program and provide functions easily and flexibly in any language. This reduces outlay and conserves resources. Furthermore, ctrlX Automation reduces the engineering outlay and the space required for machine manufacturers and integrators by between 30 and 50 percent – and increases productivity by up to 10 percent. This is made possible with more compact machines and systems, resulting in less hardware, faster installation, and significantly reduced software installations. The readiness of ctrlX Automation to incorporate future standards such as 5G or pending programming languages makes it possible for machine manufacturers to implement new types of automation concepts, be it intelligent AI systems, central server-based solutions, or distributed systems.

This article was adapted from '5G: the force is with you' published by the Bosch Rexroth web team, and for more information on ctrlX, visit https://apps.boschrexroth.com/microsites/ctrlx-automation/en